The meths burner has three short wick tubes set into a cylindrical fuel tank. In working position, half of the tank sits under the boiler and the other half protrudes outside.

The boiler is a pretty standard design, very similar to early Mamod boilers in appearance. Its dimensions are 45mm dia x 110mm. The non-functional chimney and the lever type whistle also have a Mamod-esque look to them. The safety valve, however, is a distinctive shape. The boiler is attached to the firebox by means of a brass strap. I originally thought that there should have been two straps and one was missing. However, I have since seen identical examples of this model and they all have only one strap.

Steam feed is taken from the bottom of the boiler and out through a hole in the firebox directly to the valve chest, housing the semi-rotative valve. This consists of a brass rod, cross drilled with two holes at right angles to each other, a small distance apart. The outside end of the rod has a crank, linked to a crank on the engine crankshaft, so that it rocks back and forth by 90 degrees. This causes the two holes to alternately line up with the steam and exhaust passages.

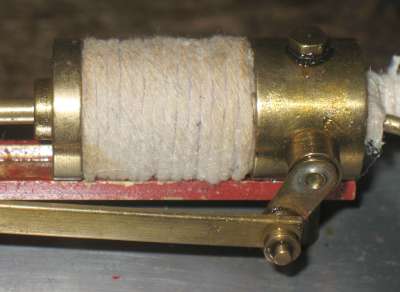

The cylinder is a substantial brass casting. It is single acting but the shape gives it the appearance of a double acting type. The cylinder is fixed (not oscillating) but it contains a long piston, as found in oscillating cylinders. This means that it does not require a cross-head guide. (This has caused excessive wear in the cylinder bore while used a lot without good lubrication). There is a plugged hole directly above the valve which, I assume, is for oiling. The bore is 8mm and stroke 20mm.

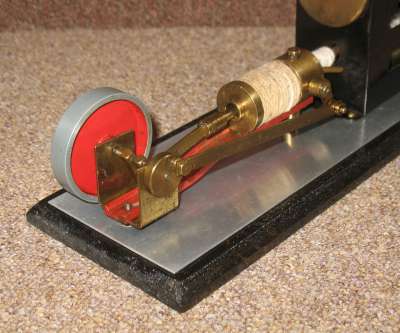

The end of the piston rod is connected to a built-up crank at the centre of the crankshaft. The crankshaft has the valve return crank at one end and a 50mm diameter flywheel at the other.

When purchased by me, the engine had been cosmetically restored to an excellent condition by the previous owner. The restorer had even gone as far as painting the insides of the three wick tubes on the burner. I don't know if this was as per the original, but it didn't last long in use! The wood base-board was, unfortunately, slightly warped. I have replaced the warped base with a new piece of stained and varnished wood. The dimensions are not exactly correct but at least it's not warped.

As acquired, the engine didn't work on steam but it did work on compressed air. I suspected this was mainly due to the large mass of brass in the cylinder, causing excessive condensation, in combination with severely worn cylinder, piston and valve, which didn't help. In order to reduce the condensation problem, I lagged the cylinder with two layers of ordinary string. I also lagged the steam feed pipe but a doubt if that had much effect. The engine now runs satisfactorily (though I'm sure it would run better with less wear).

| Make | Model | Made | Description | Cylinders | Cylinder Type |

|---|---|---|---|---|---|

| Cyldon | 13/2 | c1946 | Stationary | 1 | Single acting |

| Piston Diam mm | Stroke mm | Valve Type | Boiler Type | Fuel | Mechanical Condition |

|---|---|---|---|---|---|

| 8 | 20 | Semi-rotative | Horizontal | Meths | fair |

| Cosmetic Condition | Paintwork | Packaging | Purchased | Purchase cost | Additional cost |

|---|---|---|---|---|---|

| fair | Restored | 4/6/2006 | £62.99 |