Most of the examples made were probably binned soon after the makers left school (or maybe before). Some, however, have survived to this day, mostly traction engines but also some stationaries. As can be expected from who made them and where, the standard of workmanship varies tremendously. This example of the stationary engine leaves a lot to be desired in that respect.

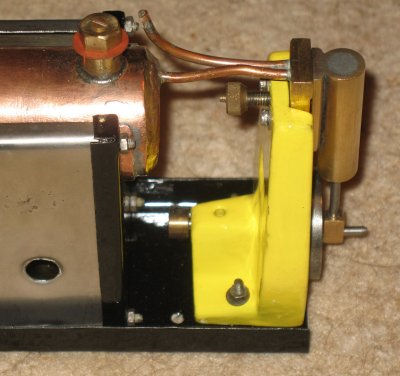

Because of their intended purpose, many diverse techniques have been used in the making. The boiler is copper with brazed end caps and soldered steam fittings. The engine frame is cast aluminium or mazac (I'm not sure which). The engine components, safety valve and burner wick holders are machined brass. The firebox, base and burner fuel tank are bent steel plate. The flywheel is turned steel. The firebox sides are chrome plated.

The book described two options for the engine frame; a cast aluminium or mazac one and a bent sheet steel one. This example has the cast version. (For an example of the sheet steel version, see here

The meths burner is a three wick type with an external tank - somewhat oversized for the boiler. The boiler is 1 1/2" diameter x 6" long copper tube with brazed end caps. The safety valve appears to be a 5/16" brass bold drilled down it's length. The hole is countersunk at the top end to take the head of a brass screw, which is sprung on the underside in the traditional manner.

The steam feed is taken directly to the engine block, with no throttle or lubricator. The cylinder and piston are of traditional single acting oscillating design; 3/8" diameter x 5/8" stroke. The con rod big end fits on a crank pin on the flywheel. The crankshaft passes through the cast frame and is standard Meccano diameter, so any Meccano component can be fitted on the rear end. This is not the most accessible of places for a power take off point.

In restoring this engine, I have retained the character of a school project; leaving the rough edges as they are. I have repainted the engine in similar colours to those on the cover of Kenneth Wells' book.The last but two photo on the left is the engine as acquired, the last but one is taken from the cover of the book and the last is a photo of the original prototype made by Wells (probably the same engine).

| Make | Model | Made | Description | Cylinders | Cylinder Type |

|---|---|---|---|---|---|

| Wells | Stationary | c 1970's | Stationary | 1 | single acting |

| Piston Diam mm | Stroke mm | Valve Type | Boiler Type | Fuel | Mechanical Condition |

|---|---|---|---|---|---|

| 9.5 | 16 | Oscillating Cylinder | Horizontal | Meths | Restored |

| Cosmetic Condition | Paintwork | Packaging | Purchased | Purchase cost | Additional cost |

|---|---|---|---|---|---|

| Restored | Restored | Feb 2007 | £23.00 |